Edm Definition Manufacturing

EDM stands for Electrical Discharge Manufacturing. A Brief Bit of EDM History The electrical discharge machining EDM process we know today started with the observations of Joseph Preistly in 1770.

I Just Love The Pattern The Metal And Touch Of Turq Semiconductor Injector Edm Hole Drilling Small Semiconductor Manufacturing Edm Semiconductor

Sometimes referred to as spark machining or spark eroding EDM is a.

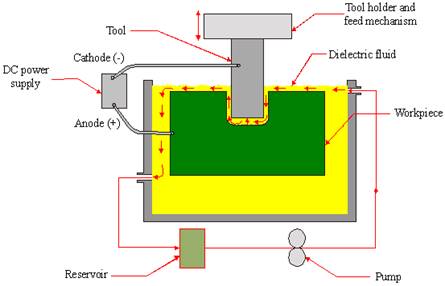

Edm definition manufacturing. Electrical Discharge Machining EDM a manufacturing process whereby a desired shape is obtained using electrical discharges is primarily used to cut hard metals and other materials that would be impossible to machine with traditional techniques. Electrochemical machining ECM is a method of removing metal by an electrochemical process. Since the introduction and acceptance of EDM in manufacturing it has been assigned to more or less typical roles and disciplines - typical meaning that vertical or ram EDM was delegated to moldmaking and mold-type operations while wire EDM was most commonly associated with the tool and die or stamping industries.

He noticed that electrical discharges had removed material from the electrodes in his experiments. Definition of Wire EDM. The EDM process involves using thermal energy to remove excess material from an object creating the required shape for a task.

Its use is limited to electrically conductive materials. Manufacturers often turn to electrical discharge machining EDM whenever traditional machining methods reach their limit. Electrical discharge machining EDM which is also known as spark machining spark dissolving kick the bucket sinking wire copying or wire disintegration is an assembling procedure whereby an ideal shape is acquired by utilizing electrical discharges sparks.

An Engineering Development Model EDM is a system acquired during the Engineering and Manufacturing Development EMD Phase that is built from approved Critical Design Review CDR drawings. Business General Business. An EDM machining process that reverses the direction of current to reduce tool wear.

It is not the most popular CNC machining process available. Additionally with EDM for Manufacturing gone are the days when manual copying and manipulating industrial data by hand or in spreadsheets is the norm. How is Electrical Discharge Manufacturing abbreviated.

Manufacturing EDM Electrodes As much as possible the electrodes are made using high speed milling with coated carbide cutters. An EDM utilises multiple forms of communication to relay and reinforce the campaign message. It may be used for development and operational testing to demonstrate maturing performance during the latter stages of development and to finalize proposed production specifications and drawings.

It is normally used for mass production and is used for working extremely hard materials or materials that are difficult to machine using conventional methods. It is the process of building an email database of customers andor potential customers and sending them communications or special offers directly. EDM is a nontraditional machining process.

Business General Business. No-wear EDM requires copper electrodes. Electrical discharge machining EDM is a manufacturing process that implements electrical sparks to form a metal shape.

The carbide tooling is usually coated with a special material to give it high wear properties due to the fact that graphite is highly abrasive. Enterprise Data Management EDM for Manufacturing from Sightline Systems Equips Quality and Process. Because of these sparks EDM is.

Metal is cooled and flushed away during the off time. You are unaware of many items that are made out of electrical discharge machining. The period during an EDM cycle when no spark exists between the electrode and workpiece.

Electrical Discharge Machining or EDM is a manufacturing operation used for shaping different workpieces into complex parts. Ram electrical discharge machining EDMalso known as conventional EDM sinker EDM die sinker vertical EDM and plunge EDM is generally used to produce blind cavities. Engineering Design And Manufacturing.

Academic Science Electronics. An EDM on the other hand is a much more lengthy process and involves more than just email communication. This is also known as electro-discharge erosion.

EDM Wire Market 2021. EDM is defined as Electrical Discharge Manufacturing rarely. It can be plastic metals for any material that may result in a specific object.

Industry Outlook Definition Business Opportunity Driving Factors by Manufacturers and Forecast till 2026 with Leading.

What Is Wire Edm Process Benefits Applications

What Is Wire Edm Process Benefits Applications

What Is Electrical Discharge Machining And How Does It Work

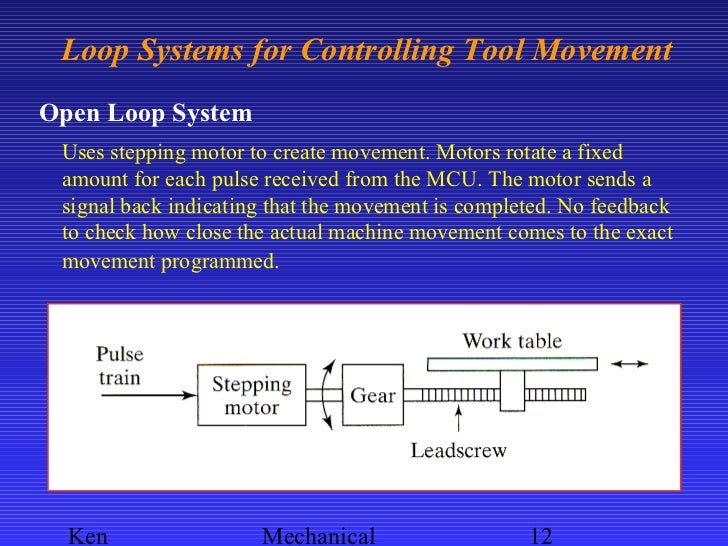

Non Traditional Manufacturing Processes

Edm Engineering Design And Manufacturing By Acronymsandslang Com

Wire Edm Procedure For Gear Prototype Manufacturing 3 2 Results Download Scientific Diagram

Difference Between Production Manufacturing And Machining

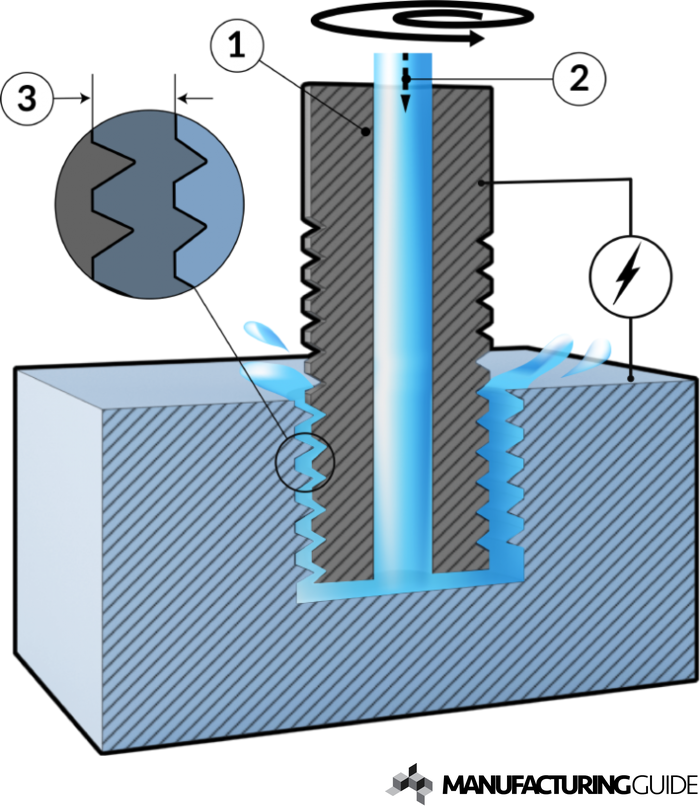

Electrical Discharge Threading Find Suppliers Processes Material

Electrical Discharge Machining Principle And Manufacturing Applications

Posting Komentar untuk "Edm Definition Manufacturing"