Edm Machine Working Principle

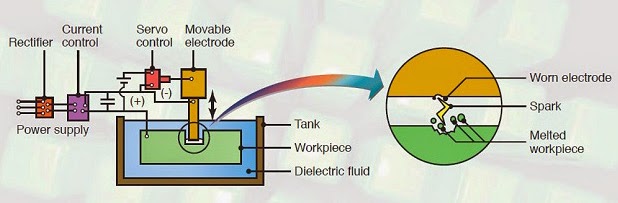

When a high potential difference is applied between the two electrodes tool and work piece which are kept a few microns apart gas bubbles start forming continuously at both. 25mm 30mm usually hollow electrode spins about a spindle much like a drill and drill bit EDM drill.

Schematic Diagram Showing A Principle Of Operation Of Edm B En 19 Download Scientific Diagram

After that with the help of a servo mechanism a small gap of human hair is maintain in between the tool and workpiece.

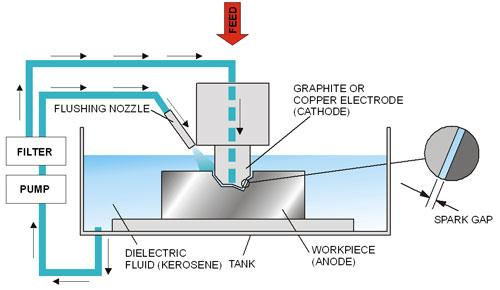

Edm machine working principle. Electric discharge machining also known as spark erosion electro-erosion or spark machining is a process of metal removal based on the principle of erosion of metals by an interrupted electric spark discharge between the electrode tool cathode and the work anode. During electrochemical machining process the reactions take place at the electrodes ie. It is often used for the production of metal parts with complex geometry.

The history of EDM itself begins in 1943 with the invention of its principle by Russian scientists Boris and Natalya Lazarenko in Moscow. An EDM machine is the piece of equipment used to carry out this manufacturing process. As the spark jumps across the gap material is then removed from the work piece and the electrode.

In EDM a potential difference is applied between the tool and workpiece. If the wire breaks while cutting a part the machine senses the break re-threads the wire and resumes the cut where the wire broke. The Wire EDM process is a subtractive manufacturing process.

EDM spark erosion is same as electric spark which burn a small hole in a piece of metal through witch it contacts. The principle behind EDM was first observed in 1770 by Joseph Priestley who was experimenting with electrical discharges. Working of Electrical Discharge Machining EDM In EDM first the tool and wp is clamped to the machine.

Basic Principle Mecasoft EDM is a machining technique for electrically conductive materials in which the tool consists of a fast and controlled continuous series of electric arcs between an electrode and the workpiece. Electrical discharge machining also known as spark machining spark eroding die sinking wire burning or wire erosion is a metal fabrication process whereby a desired shape is obtained by using electrical discharges. A water jet or air jet guides the wire through the work piece.

Electrical discharge machining process works on the basic principle of spark generation and metal removed by spark erosion. Material is removed from the work piece by a series of rapidly recurring current discharges between two electrodes separated by a dielectric liquid and subject to an electric voltage. The electrode is electrically charged by a servo-controlled generator producing the spark.

In EDM the tool electrode and the workpiece are connected to the two poles of the pulse power supply respectively and immersed in. A small 010 118 dia. The tool and workpiece is immersed in dielectric medium kerosene of deionised water.

Wire EDM machining works by creating an electrical discharge between the wire or the electrode and the work piece. The process is as follows. EDM stands for Electrical Discharge Machining.

Uses of a Sinker EDM Machine. High-speed small hole EDM is a specialized field of electrical discharge machining. This is a process where electrical discharge sparks come from the wire or electrode which basically erodes the material to make the required part.

Essential - Both tool and work material are to be conductors. Modern wire EDM machines provide automatic threading. Electrical discharge machining EDM also known as spark machining uses either an electrode for EDM sinking or a brass wire for wire EDM.

The working principle in ECDM is by combination of thermal and chemical mechanisms. Electro discharge machining is also called as spark machiningspark erosion machining. The machine automatically makes the necessary mechanical and electrical connections.

ECM working is opposite to the electrochemical or galvanic coating or deposition process. At the anode workpiece and cathode tool and within the electrolyte. He noticed that the sparks had eroded some of the electrode material.

Working Principle of Electrical Discharge Machining Process. The spark generated by this process produces heat which remove metal by erosion and evaporation. Electro Discharge Machining EDM is an electro-thermal non- traditional machining process where electrical energy is used to generate electrical spark and material removal mainly occurs due to thermal energy of the spark.

The tool is fed up by the Servo Feed Unit which can move downward in a. Wire EDM is a non-conventional machining process which is based on the principle of electrical discharge machining EDM. Because there are visible sparks in the discharge process it is called electrical discharge machining.

It is a process of metal removal based on the principle of material removal by an interrupted electric spark discharge between theelectrode tool and the work piece. EDM Working Principle. Principle of wire cut EDM 2011-11-04 CNC wire cut EDM machine puts impulse voltage between electrode wire and workpiece through impulse source controlled by servo system to get a certain gap and realize impulse discharging in the working liquid between electrode wire and workpiece.

The workpiece is fixed in the dielectric container using a fixture.

Electrical Discharge Machining Principle Working Equipment S Advantages And Disadvantages With Diagram Mech4study

Electrical Discharge Machining An Overview Sciencedirect Topics

What Is Electrical Discharge Machining And How Does It Work

Electrical Discharge Machining How Edm Machine Works

Mechanical Engineering Electrical Discharge Machining Edm Principles

Electrical Discharge Machining An Overview Sciencedirect Topics

Principle Of Electric Discharge Machining Download Scientific Diagram

What Is Electrical Discharge Machining Edm Process And How It Works Mechanical Booster

Mechanical Engineering Electrical Discharge Machining Edm Principles

Electrical Discharge Machining Edm

Posting Komentar untuk "Edm Machine Working Principle"