Edm Wire Cut Time Calculation Formula

Wire-feed Speed deposition rate5 weight of wire per foot lbft 125 00054 4444 ipm Of course the travel speed for a one-pass 38 in fillet weld at a 12 lbhr deposition rate would be 831 ipm as calculated below. In general the auto-threader alone can improve your capital equipment pay back on a Wire machine by 2 or 31.

Wo2016194072a1 Machining Time Estimating Method For Wire Electrical Discharge Machine And Control Device For Wire Electrical Discharge Machine Google Patents

Brass wires for EDM are typically an alloy between 6337 American and European to 6535 Asian Volume 2 Issue 3 March 2017 International Journal of Innovative Science and Research Technology.

Edm wire cut time calculation formula. How Wire EDM Works. Previously GE used as many as 27 different operations many of them milling. The Automatic Wire Threader made it possible for work to be scheduled into the Wire EDM machine based upon the needs of the operator rather than the length time of cut.

EDM can be used to machine difficult geometries in small batches or even on job-shop basis. Rpm 12 sfm π cutting diameter in inches rpm 1000 mmin. Wire EDM reduced the delivery to 2-4 weeks.

This does not include set up time. You have to know how many square inches per hour you can cut with the size wire you are using also dependent on the thickness of your work piece divided into the number of square inches on the job to come up with a number of hours or minutes required to do the job. Weighing over ten thousand pounds and can cut over twenty inches thick.

Create an app in minutes. Most machines can cut tapers of 20-30 degrees depending on workpiece thickness. When the reference rate for the actual machining speed Va is P the reference rate for the predicted machining speed Vp is 100P.

Work material to be machined by EDM has to be electrically conductive. Log in to post ratingcomment. General Electric uses 36 wire EDM machines to cut steam turbine bucket roots.

Material removal rate-Wire Electric Discharge Macining EDM description. In addition to the X-Y table travels wire EDMs have U V travels for providing the movement to cut tapers. Automatic Wire Threaders AWT are usually standard equipment on most models.

1 shows schematically the basic working principle of EDM process. The formulation of the EDM roughing time for the case of using only one generator setting during the roughing operation. Volume i the volume removed during the ith step.

Wire edm mrr unconventional machining non traditional machining. When using standard 0010 O brass wire you can expect a consistent reliable wire EDM cutting speed of approximately eighteen to twenty inchhour. N i 1 efficiency flushing ref i roughing i i i C C MRR Volume EDM Time 2 With.

I the ith calculation step. Job workers using this formula as given - total hrs. In Single pass Single cutTotal Path length x job thickness 1500 total hrs.

In Double pass Double cutTotal Path length x job. Wire cut EDM 08282007 812 AM for a 25 mm thick hardened die steel plate you can assume 1mmmin cutting speed for roughing 08mmmin for finishing 2-3 mmmin for providing relief. π cutting diameter in millimeters.

Wire 2 Cuts Cut Length 5769 TPF 2 Cut 142 Formula 5769 142 406 hours total cut time. Prior delivery with conventional methods required 12 weeks. HEAT smokes the Wire EDM competition cutting parts 18 to 44 percent faster while holding tolerances of straightness to 00005 inch TIR with one pass and 00002 inch TIR with two passes.

EDM is mainly used to machine difficult-to-machine materials and high strength temperature resistant alloys. Unfortunately the EDM process creates minute chips and debris that can adversely affect the reliability of this transport system. HEAT is a new advancement from Makino in Wire EDM Technology that dramatically reduces cutting times in poor flushing conditions while maintaining exceptional part straightness.

Electrical Discharge Machining EDM-calculation of material removal rateempirical approach description. The resulting value will give you the machining time. I was just wondering if some one could give me a rough costtime estimate to wire edm out 2 or 3 6 or so diameter 50or so tooth gear from either 14-12 thick plate or round.

N the total number of calculations steps. Average Linear Feed Rate value shown for the last pass of the cut you will be taking. The speed is directly proportional to the thickness.

Rough timecost estimate to wire edm a 50tooth 6 dia gear. Now it can cut the entire bucket periphery in one pass. I have found this formula quite accurate you can save upto 10 time.

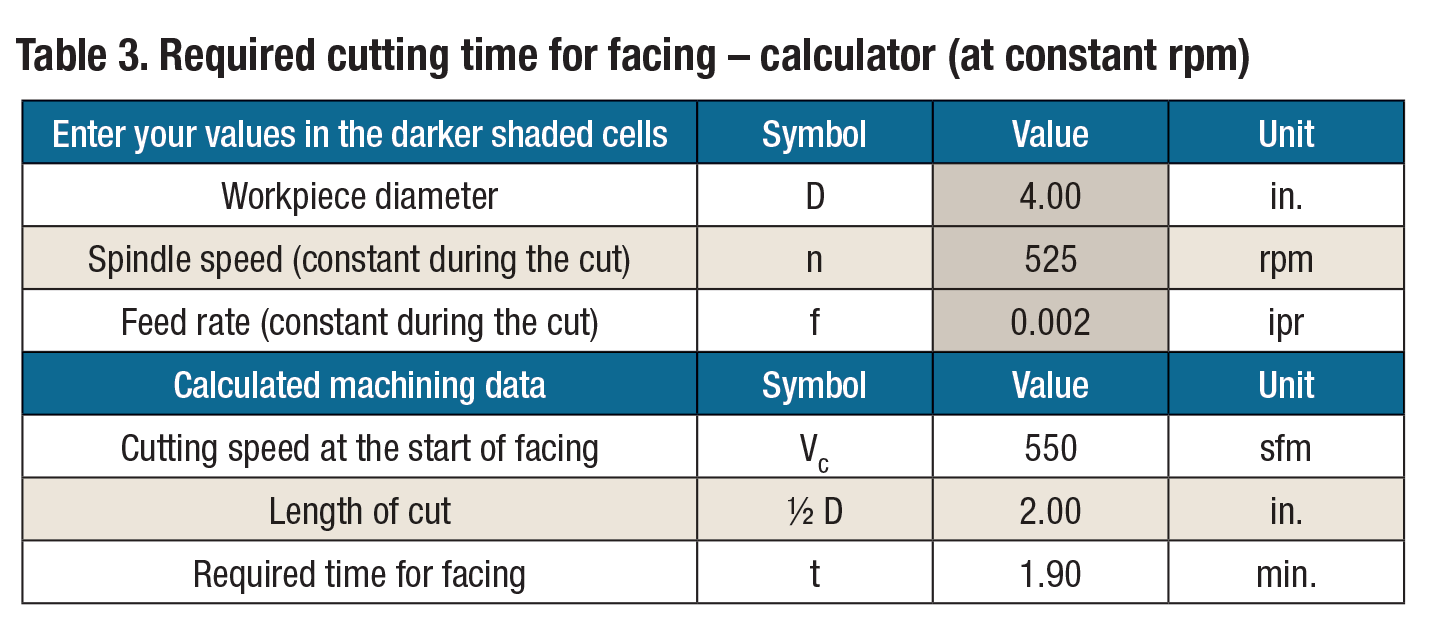

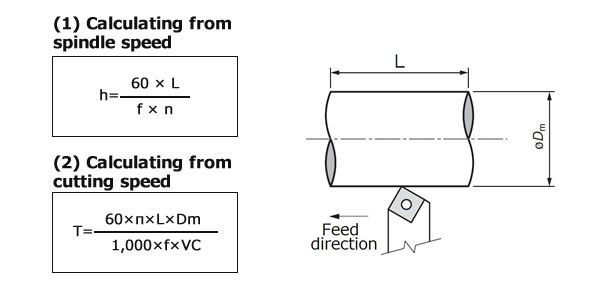

To calculate the time take the periphery of the part one time around divided by the ALF. At constant cutting speed a CNC lathe automatically applies the correct rpm based on the following formulas for inch and metric systems.

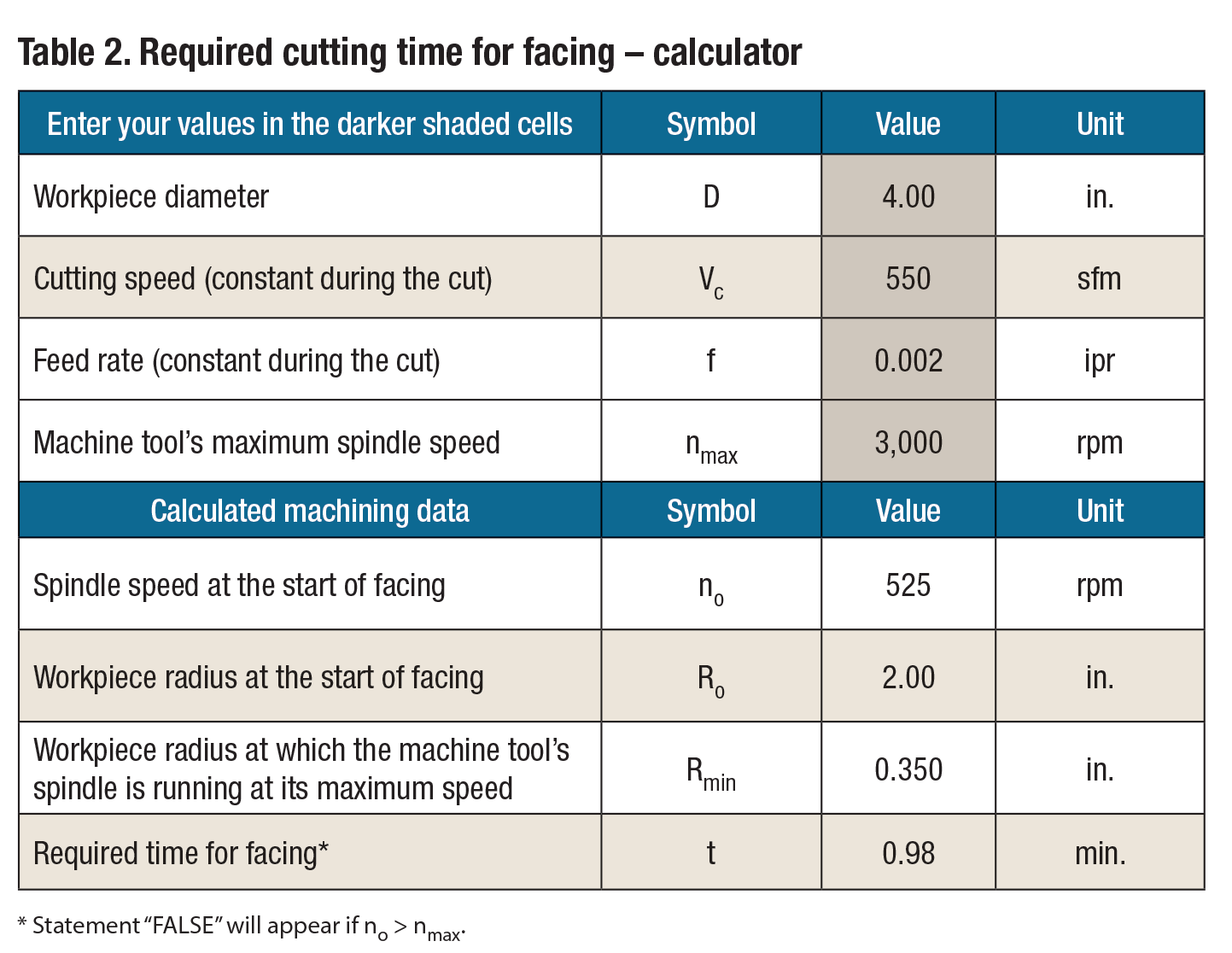

Cutting Time For Facing Cutting Tool Engineering

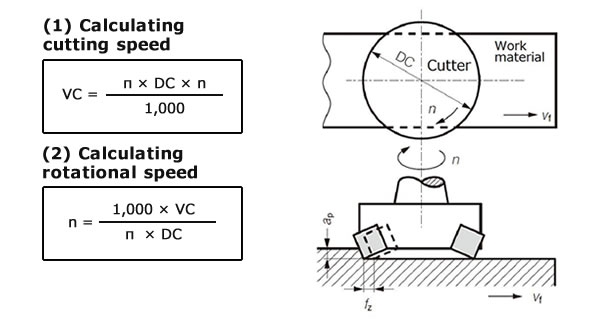

Difference Between Cutting Speed And Cutting Velocity

Cutting Time For Facing Cutting Tool Engineering

S N Ratio Calculation For Machining Time Download Table

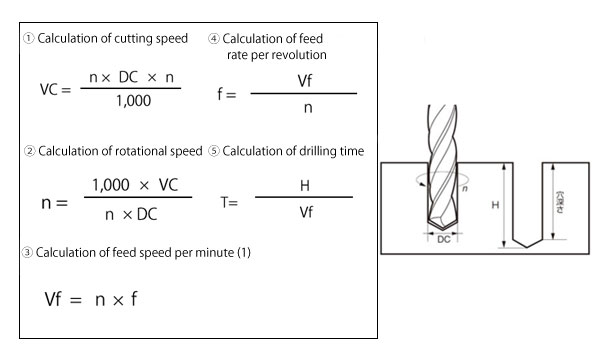

Formula To Calculate Cutting Process A L M T Corp

Formula To Calculate Cutting Process A L M T Corp

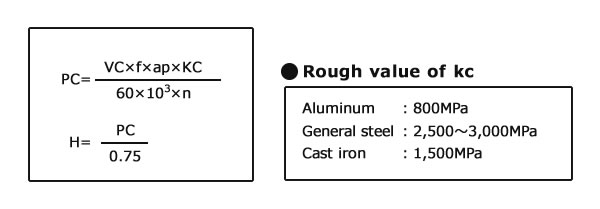

Formula To Calculate Cutting Process A L M T Corp

S N Ratio Calculation For Machining Time Download Table

Formula To Calculate Cutting Process A L M T Corp

Cutting Time For Facing Cutting Tool Engineering

Posting Komentar untuk "Edm Wire Cut Time Calculation Formula"